Why should we consider a lighting upgrade?

If you’re interested in saving money and energy, keep reading

SAVE ENERGY=$$$$$

The average kilowatt rate in the USA is ten cents per kilowatt hour and climbing. If, for example, you leave a 100-watt bulb running continuously (730 hours a month), and you pay10¢/kWh, your cost to run the bulb all month is 100 x 730 ÷ 1000 x 10¢ = $7.30. Per Bulb. What if you could get the same amount of light but only use 18W, reducing that $7.30/per bulb to 1.31!

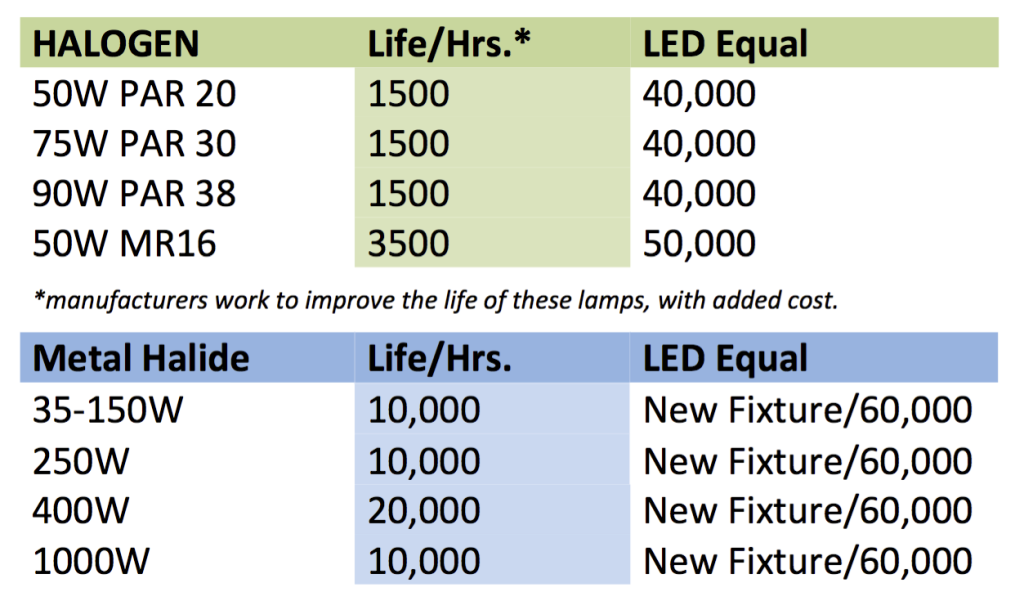

In addition to reducing your operating costs, you’ll reduce your maintenance costs. The lighting industry recommends a group re-lamp, when 10% of lamps are out, but most companies don’t do this. Instead, they have someone in the maintenance department get on a ladder, remove the lamp, determine it’s wattage and (if he’s savvy) color temperature and go to the local store for a replacement bulb, paying the highest cost possible. As bulbs reach end of life—which can vary significantly from bulb to bulb—that facility manager spends a lot more time in the air, costing the company a lot more money, than they’d spend with a simple group re-lamp. Consider the chart below which shows rated life of halogen and HID lamps*:

*lamp life is determined by manufacturers to be when half the lamps in a test group have failed. So, if a lamp has a 20,000 rating, half of those lamps will be out at 20,000hrs.

SUMMARY

Changing your screw-in halogen lamps will pay for themselves in a matter of months. Depending on the age of existing fixtures—and especially your application and light source–here are some considerations:

If you currently use an HID (metal halide or high pressure sodium) light source and upgrade to LED, you’ll:

- Reduce your lighting energy consumption (utility bill) by up to 3/4ths.

- Maintain the initial light levels for the rated life of the LED’s (HID lamps depreciate in their light output by almost 50% by the time you have used half the lamp life).

- Maintain the same color of light for the rated life of the LED’s (HID has poor color rendering, making it more difficult to discern color or text).

- Reduce lamp/ballast changes by at least six times.

If you currently use a Halogen light source and upgrade to LED, you’ll:

- reduce your lighting energy consumption by half.

- significantly reduce the heat caused by this lamp source.

- virtually eliminate maintenance by not having to change burned out lamps.

BOTTOM LINE

Have Twin Supplies come out and walk through your facility. We’ll explain why upgrading certain fixtures will save you the most energy and maintenance. We can add controls to any fixture we offer, to reduce your maintenance, extend the life of the LEDs, and save you even more!

We have designers on staff who can re-design areas of your facility that might have been reconfigured, where the old lighting no longer does its job.

We offer full turnkey services that include:

- Conduct Initial audit

- Perform Energy Calculations and photometric layouts

- Devise Solution

- Turnkey job: purchase, install new and re-cycle old product

- Interface with utility and grant programs, to see if there are ways to offset costs

- Explain Financing/Leasing, so energy savings will pay for the job